REMEDIATION SOLUTIONS

RITTER SYSTEM MEMBRANE TECHNOLOGY

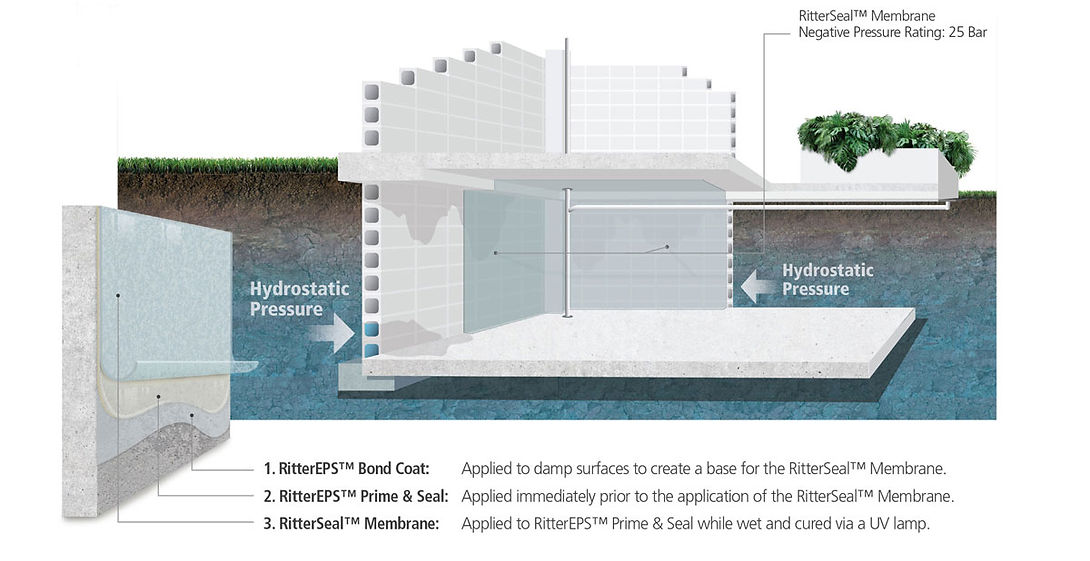

A key feature of RitterSystems™ Waterproofing Membrane is its ability to be used as an effective tanking solution in negative pressure environments. In particular, RitterSystems™ is able to achieve this high adhesive even when applied to pre-existing wet or damp surfaces.

WET WALL TANKING

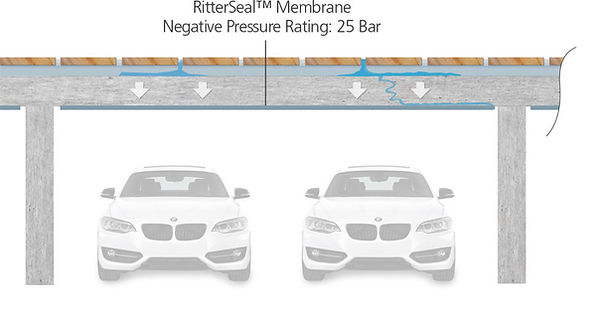

NEGATIVE PRESSURE - SLAB SEEPAGE

A major problem for residential highrise developments is slab seepage. RitterSystem Waterproofing membrane can offer a quick and effective solution for preventing or redirecting water away from vehicles and basement storage areas.

The strength and durability of RitterSeal™ delivers significant benefits for many waterproofing applications. In the case of planter boxes and rooftops, the strength of the product means there is no requirement for additional membrane protection. Also, unlike many other membrane systems, its high adhesion value mitigates risk of delamination negating the need for flashing.

POSITIVE PRESSURE APPLICATIONS

Planter Box Cross Section

Roof Top Parapet Section

Door Entry onto a Tiled Deck

MEMBRANE ADHESION ONTO DRY BESSER BLOCK

MEMBRANE ADHESION ONTO WET BESSER BLOCK

MEMBRANE ADHESION ONTO PRECAST CONCRETE

MEMBRANE ADHESION ONTO PVC PERMANENT FORMWORK

RitterSystems™ Waterproofing Membranes are supplied in rolls of approximately (1m x 10m). The membranes can be cut to any shape, applied and cured in minutes.RitterSeal™, the most commonly used waterproofing membrane offers excellent water and UV resistance with superior adhesion properties to most substrates, including concrete, timber, metal. The membranes are cured through exposure to UV radiation, either via the sun or by using a high emission UV radiation lamp.

HOW IT WORKS

• Quick and easy application

• Controlled quick curing process

• Impact-resistant 55kj/sqm

• Negative pressure - 1,000 KPA

• UV stable 30 years +

• Potable

Tensile Strength

ASTM D 882

>25 N/mm2

Elongation

ASTM D882

5%

Puncture resistance

ASTM E154

>250N

Tear resistance

ASTM D5147

>450N

Adhesion to Concrete

ASTM D1000

5 N/mm2

Adhesion to Steel

ASTM D1000

6 N/mm2

Adhesion to Dense board

ASTM D1000

4 N/mm2

Adhesion to Plywood / OSB board

ASTM D1000

2 N/mm2

Hydrostatic Pressure

BS EN 12390

25 bar-No leakage

Chemical resistances

D 543

2.5 – 11ph